How Food ERP Distribution Software Delivered End-to-End Control

To help Truffle Crafters keep up with growing demand and reduce manual work, we implemented Odoo 18 Enterprise, hosted on Odoo.sh. The new system connects Production, Inventory, and HR, giving the team a full view of operations in one place and saving time every day.

Using the Sales (with Shopify integration), Manufacturing, Quality, Inventory, Purchase, HR, and Accounting modules, the system supports batch production, real-time labor cost tracking, end-to-end stock control, vendor management, and employee cost profiling.

Workflow Overhaul Made Possible by ERP Software for Food Distribution

- Automated Bills of Materials (BoMs) to reduce manual setup and improve accuracy

- Barcode scanning for real-time tracking of inventory and production status

- Labor cost tracking by individual employee, based on role, skill level, and contract

- Work order assignment to specific people (not just roles), improving accountability

- Dashboards and reports for quick visibility into production, costs, and performance

- Up to 500 daily orders supported, with efficient resource and labor planning

How Odoo Implementation Transforms Daily Work—from Production to Shopify Sales

After our partnership, the client achieved impressive results, with key modules implemented that streamlined operations and boosted overall efficiency.

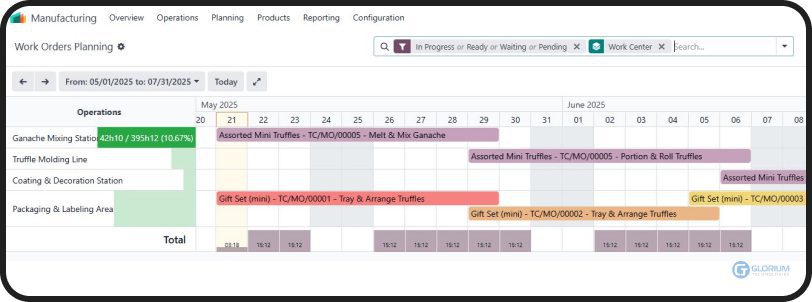

Manufacturing

Manages the full production process, from start to finish. Allows creation of detailed work orders, real-time tracking of tasks, and assignment of specific employees to each step. Helps plan batches, monitor progress, and reduce delays.

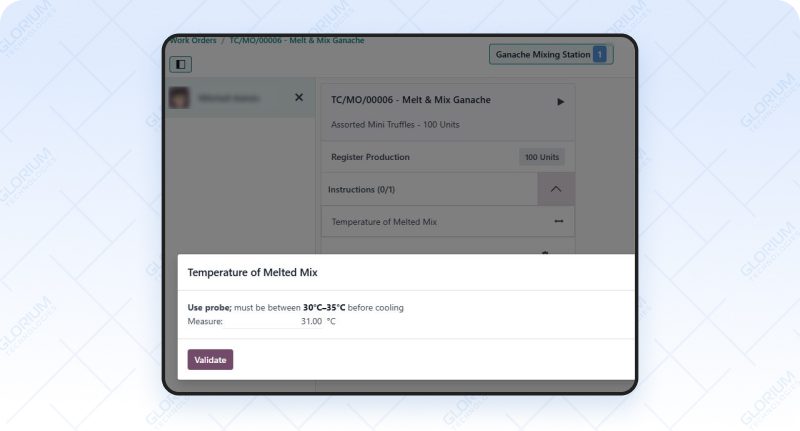

Quality

Ensures consistent product quality with built-in checks at every stage—ingredients, in-process items, and finished goods. It facilitates the tracking of issues, establishes quality standards, and links these checks directly to work orders or batches.

Inventory

It keeps track of all ingredients, packaging, and finished products in real time. Supports barcode scanning, automatic stock updates, and alerts when items are running low. Handles multiple storage areas with ease.

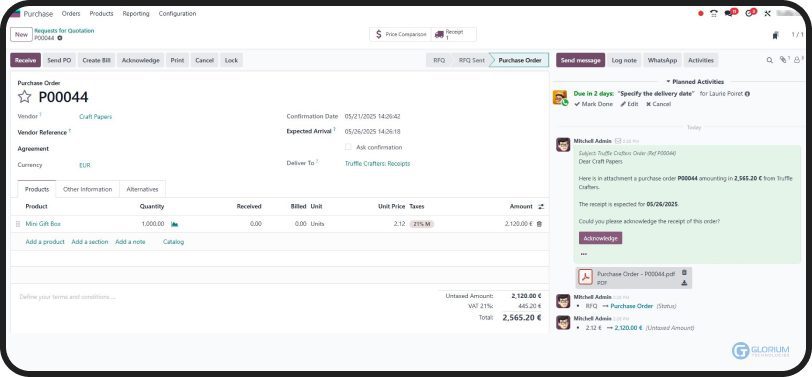

Purchase

Automates ordering materials based on current stock and future needs. Compares prices across vendors, manages lead times, and helps avoid shortages or overstocking.

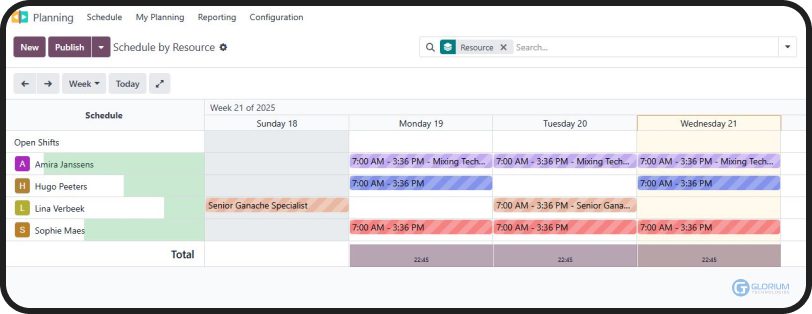

Human Resources (Employees, Timesheets, Planning)

Tracks employee profiles, roles, skills, contracts, and schedules, allowing managers to assign work orders, log hours via timesheets, and plan shifts. It integrates HR data seamlessly with manufacturing and cost reports.

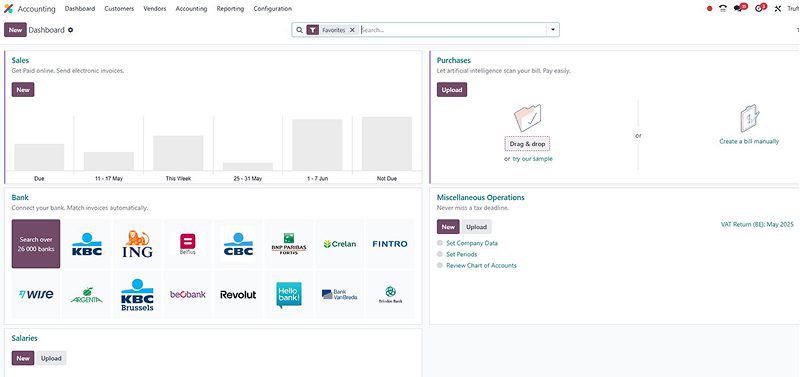

Accounting

Calculates real labor costs based on actual hours worked, employee roles, and contracts. Connects with HR and manufacturing to track production costs accurately. Simplifies vendor payments, invoicing, and financial reporting.

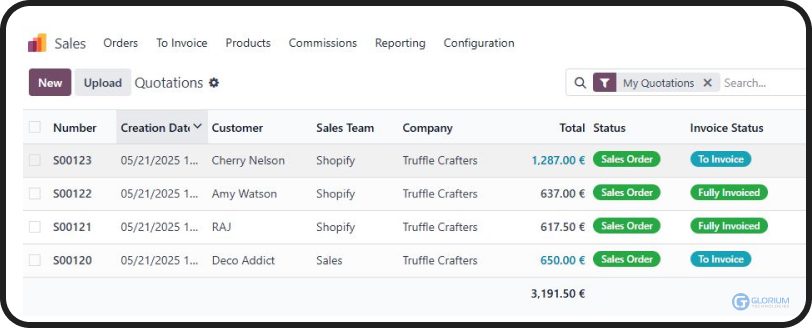

Sales (with Shopify Integration)

Connects Odoo with the Shopify web store. All online orders flow directly into Odoo for production and delivery. Inventory updates automatically, and sales data is available for reporting and planning. It aids in preventing overselling and enhances the overall customer experience.

A Clear Three-Phase Plan for Bringing the Odoo ERP System Live

The estimated timeline for the project was 14–18 weeks, starting with:

- Manufacturing

- Inventory

- Quality

Then extending to HR and Accounting integration, and Sales (with Shopify Integration)

Phase 1: Planning & Configuration

- Process mapping workshops

- Setup of Manufacturing, Inventory, and Work Center modules

- Employee cost profiles by role, skill, and contract

Phase 2: Labor Cost Tracking Integration

- Work order–level employee assignments

- Shop floor timers + digital worksheets

- Labor data linked directly to product cost analytics

Phase 3: Training & Optimization

- Role-specific training for operators and managers

- Planning dashboards for live workload balancing

- Quality checks as mandatory digital steps before order closure

Cost Reduction Meets Real-Time Visibility in a Unified Odoo Environment

Reduction in Production Costs:

Glorium Technologies helped to achieve a 10% reduction in production costs. Each work order now tracks actual hours worked by each employee. Odoo calculates labor costs based on real inputs, not estimates, so Truffle Crafters always knows how much each batch really costs to make.

Labor Cost Transparency:

The integration of Odoo’s labor cost tracking functionality provided complete transparency into labor expenses. Each employee’s time and associated costs are now accurately tracked at the work order level, resulting in 100% visibility into labor expenses compared to the previous system of rough estimates and averages.

Time Savings:

Previously, the team spent 20 hours per week reconciling production schedules, orders, and labor hours manually. By automating work orders, HR data integration, and real-time inventory tracking, Truffle Crafters now saves 50% of this time, freeing up more resources for production activities.

Improved Reporting Efficiency:

Before the implementation of Odoo, reporting would take days. With Odoo’s real-time data synchronization and automated reporting, Truffle Crafters has seen a 90% reduction in reporting time, allowing for quicker decision-making and a more agile business response.

Connected Production, Inventory, and HR

All departments now work in sync. As production moves forward, inventory updates automatically, and HR can see who’s working on what and when. There’s no more need to manually match up spreadsheets or schedules.

Sales with Shopify Integration

Online orders from Shopify were automatically pulled into Odoo. It reduced manual data entry, kept stock levels accurate, and ensured the production team is always working from the latest demand. Now customers get faster, more reliable service.